ND Engineering

The printing machine professionals from the Palatinate

Under the direction of Ralf Neumaier and Christian Dotzauer, five employees develop new printing machines and individual and spare parts.

Four machine builders and an expert in hardware and software engineering convert or expand printing machines and take care of process optimization.

"We try to market what's in our heads and to put our creativity on paper." Ralf Neumaier

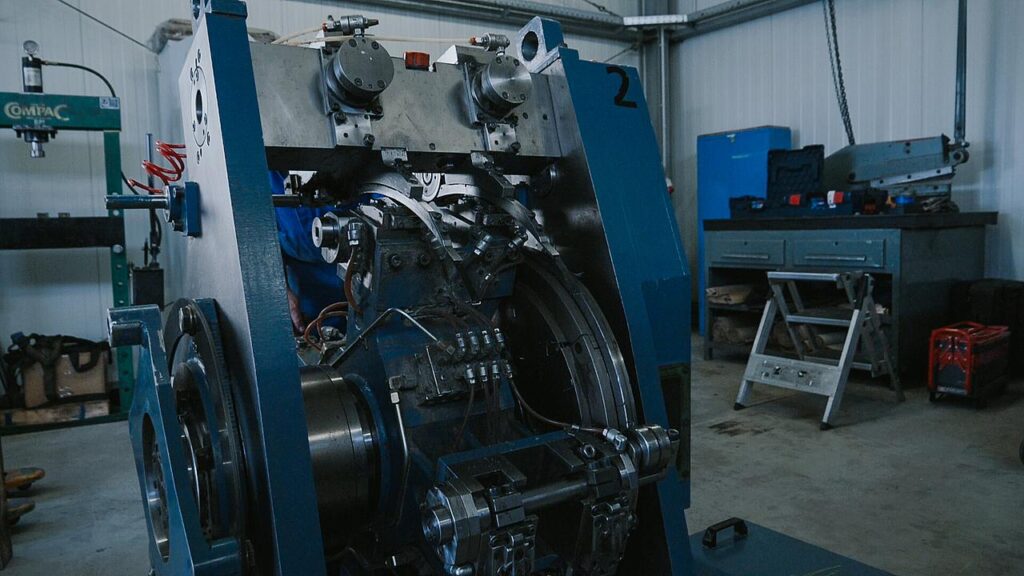

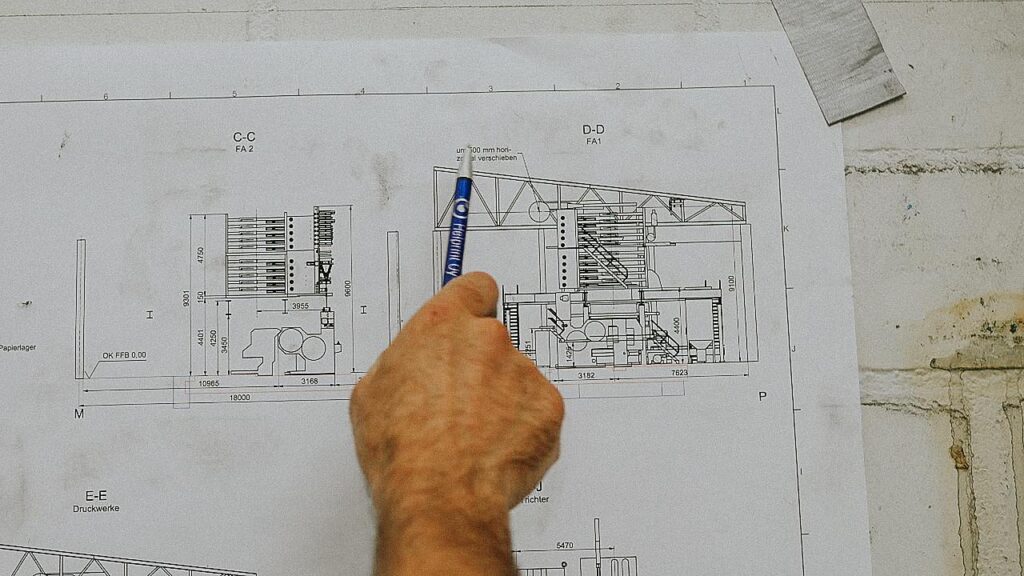

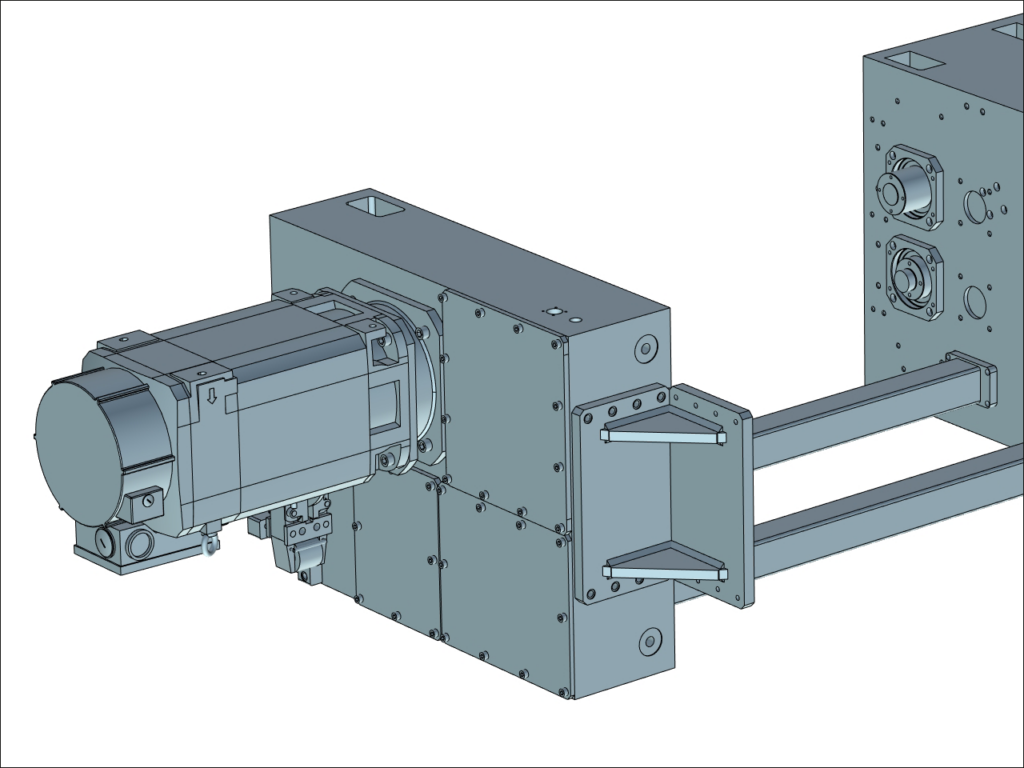

More than 1.5 years passed from dismantling in Munich to assembly and the start of production in Mönchengladbach. The order: move the machine, which was initially on an intermediate deck, to the ground floor. To do this, the team has lengthened individual parts and roller carriers, Prestressing station and cable station repositioned.

The steel substructure had to be adapted accordingly and equipped with access platforms and stairs. The engineers attached components that were already available in Mönchengladbach to the rotary gravure press.

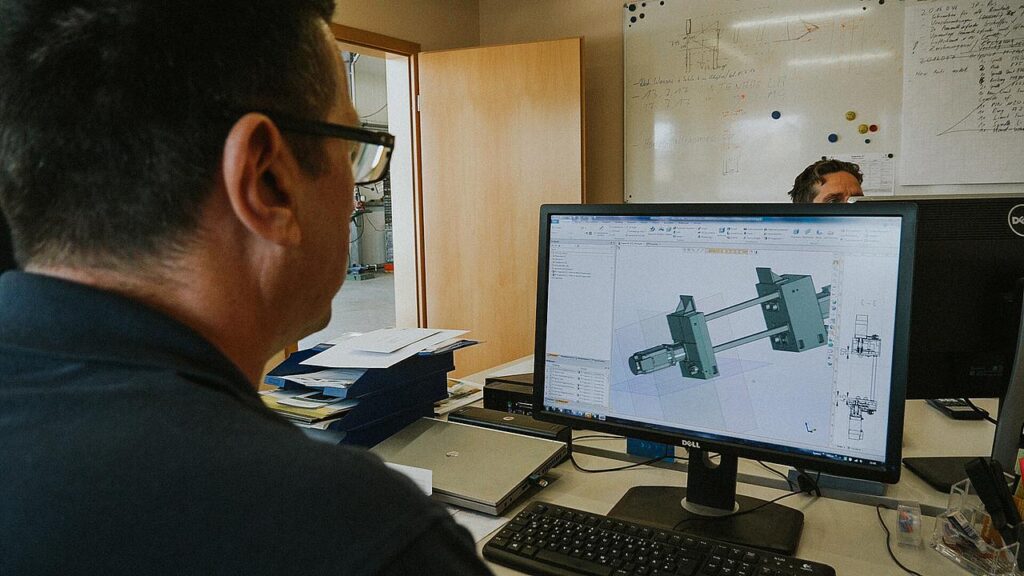

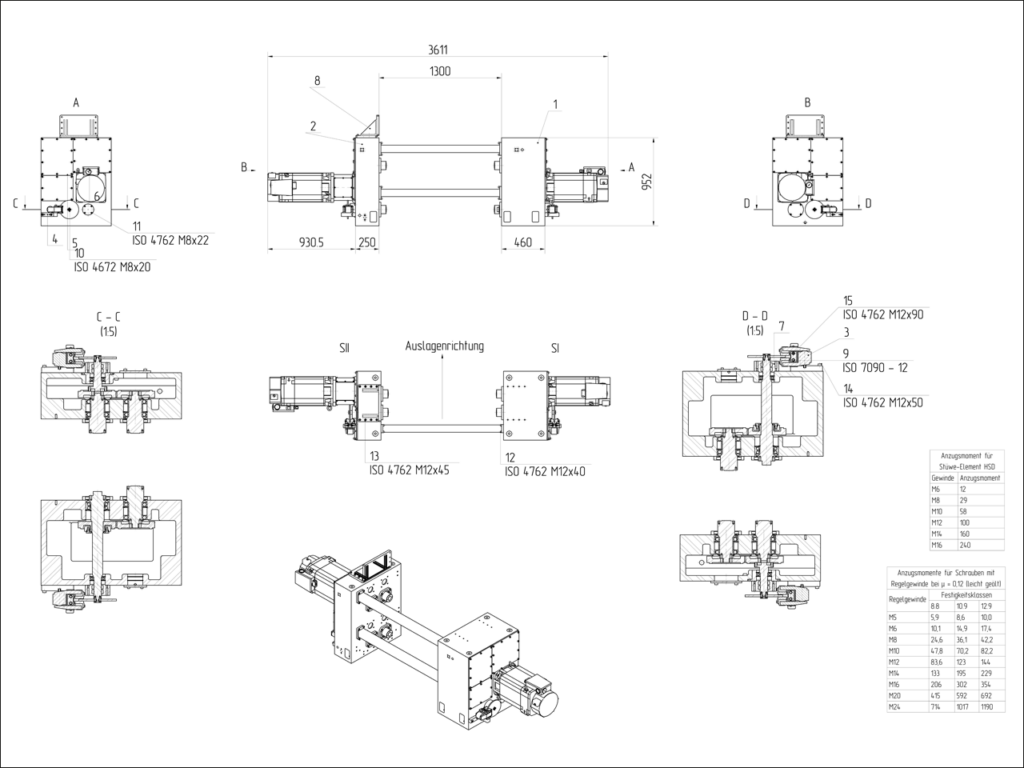

“When the order is tough, the design always starts first,” says Ralf Neumaier. TENADO CAD 3D is used for every construction at ND Engineering . The diversity of the program and the extensive interfaces enable a smooth exchange with colleagues and clients. Load the design as a DWG/DXF, process it further and pass it on for implementation.

This is particularly important for large-scale jobs such as relocating the rotogravure press. The ND Engineering team created around 60% of the new designs with TENADO CAD 3D . Due to the large number of design tasks, they have given part to an external office.

Compatibility and uncomplicated exchange between the offices ensured a smooth and relaxed process.

The project still occupies the printing press professionals today, because maintenance and repairs are part of all aftercare orders. If something isn’t right, TENADO CAD 3D is used again.

A collaboration that pays off for ND Engineering.

"Since we've been using TENADO CAD 3D, it's given us a real boost in orders." Ralf Neumaier