Denis Letz

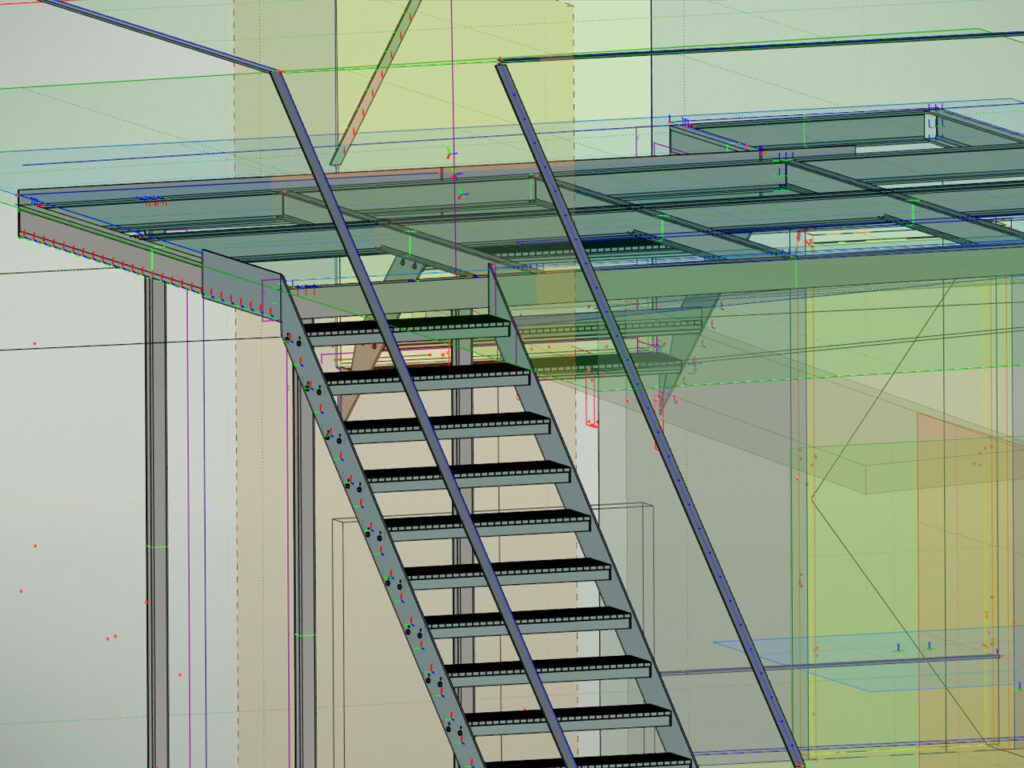

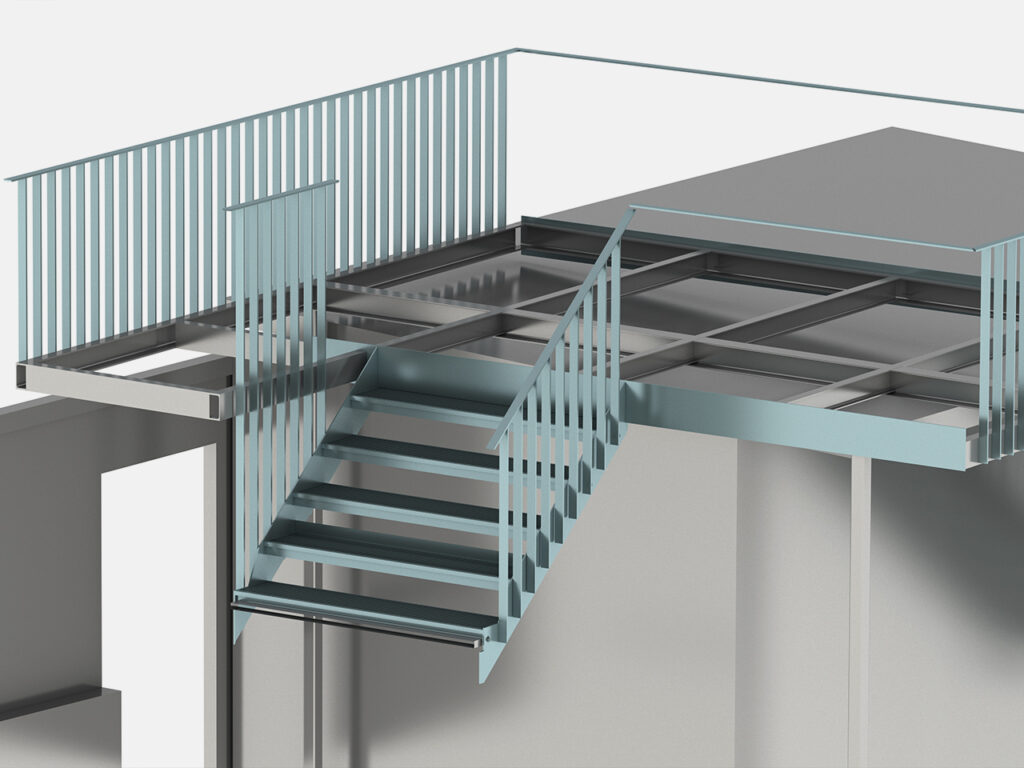

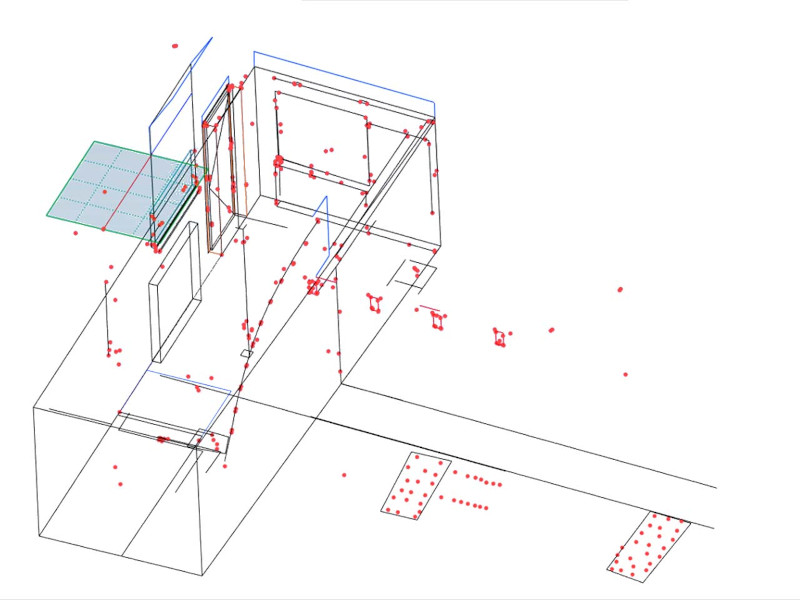

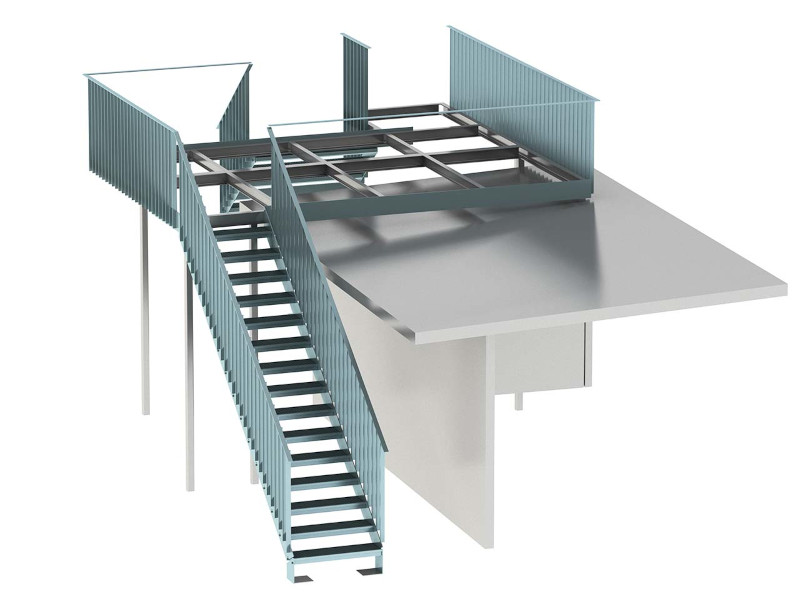

With TENADO METALL 3D you design effectively, save time and money. In combination with the data from laser scans, the measurement can also be accelerated.

Advanced technology saves time

Master metal worker Denis Letz became self-employed in 2012. Since then, the company based in Diedorf (Augsburg district) has grown to 11 employees. TENADO METALL 2D was there from the start. Today, the company “Stahl- und Metallbau Denis Letz” stands for high quality and a broad portfolio of services. With TENADO METALL 3D, new possibilities were added to effectively save time and money.

“We have projects in the field of steel and metal construction, building metalwork and everything to do with stairs, railings, balconies and canopies. We also work for industry,” reports Denis Letz. “I already knew TENADO METALL 2D from my previous company and worked with it. Of course, when I started my own business, I didn’t have much time. That’s why TENADO METALL 2D was one of the first purchases.”

Effortlessly meet higher requirements

Error-free working with laser scans